E-Sharp News

April 2017

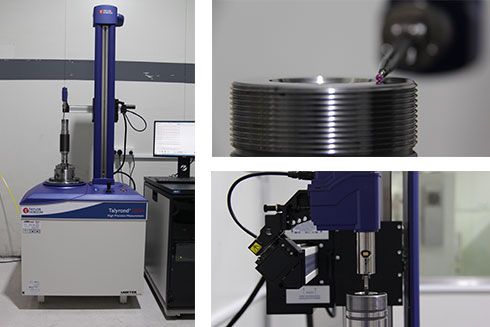

We recently installed a Danobat-Overbeck ID- 400 L precision internal grinder and Taylor Hobson Talyrond 585H at our head office in Melbourne, Australia. The new machines represent a significant investment in our machine shop and builds our capabilities in process technology. A core strength of ANCA, the machine shop is a valuable centre of excellence and the investment boosts the internal grinding and precision measurement capabilities.

Mark Patman, Manufacturing Operations Manager at ANCA said: “In the Melbourne factory we have a large modern machine shop and dedicated precision grinding cell that feeds directly into the assembly of our products. Both pieces of equipment will integrate into our already established internal component manufacturing function, supporting greater flexibility to the overall supply chain and reducing lead times.”

We are continually striving to improve our productivity while maintaining the highest quality of our machining components. The purchase of a Danobat-Overbeck ID-400 L precision internal grinder provides additional capacity in the manufacture of precision rotary components. To support the purchase of the Danobat-Overbeck, we also purchased a Taylor Hobson Talyrond 585H fully automated roundness/cylindricity measurement and analysis instrument.

Mark continued: “To select the right equipment, ANCA studied several leading internal grinder manufacturers along with roundness checker manufacturers. It was a very thorough review and involved visiting the manufactures and assessing their products to ensure they would meet our needs.”

The team selected a Danobat-Overbeck ID-400 L internal grinding machine because it offered the longest bed, fastest axis speed, most powerful spindles and largest working envelope. Its one-piece natural granite base offers exceptional rigidity and stability benefits which is ideal for internal grinding. The Talyrond 585H from Taylor Hobson was chosen for its world class software and measurement analysis capability.

“I am pleased with the new equipment, but more importantly the companies we have partnered with – Danobat group and Taylor Hobson. Our customers are demanding tighter and tighter tolerances and this market requirement eventually flows down to the accuracy of the components produced and in turn the accuracy of the machines and processes making those components.”

“We have been responding to this by investing in new equipment but also with the right partners that can support us in producing higher accuracy parts. As a team, we all worked hard to achieve some challenging tolerances and I want to give credit to all involved for delivering a greatly improved capability to ANCA.” Mark concluded.

Our continued investment in the best capital equipment in the market demonstrates the company’s commitment to manufacturing and our dedication to continuous improvement.