E-Sharp News

December 2011

For short batch grinding the goal is “first tool right - every time”. For longer batches, we add another goal - “each tool just like the first one”. ANCA’s new automatic wheel probe takes you one big step closer to this ideal by qualifying your wheels automatically with a repeatability of +/- 5 microns (+/- 0.0002”).

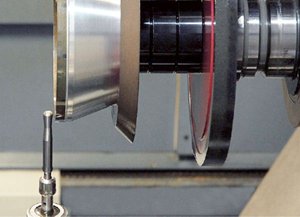

To get accurate tools from a tool grinder, you need to enter the exact dimensions and locations of your wheels; a process called wheel qualification. Until now, the usual way of qualifying a wheel has been to insert a qualification bar (Q-bar) in the collet and touch the wheel to the bar, while spinning the wheel slowly to pick up the high points. Some operators remove the wheel pack and measure it in an external presetter. Both methods have obvious drawbacks; they are manual, time-consuming processes and can introduce unwanted errors. In fact, we ran a test with Q-bar qualification and found a variation of up to 70 microns (.0027”) between readings from different operators! Even with a quality presetter, it’s impossible to ensure the wheel pack is remounted in the machine at exactly the same orientation every time, which can also introduce small errors.

Automatic Wheel Qualification

The new automatic wheel probe from ANCA virtually eliminates first tool rejects on many tool types. It does this by probing the dimensions and locations of the wheels in your wheel pack without removing the wheel pack from your machine and without operator intervention. This makes it highly accurate - approximately 10 microns (0.0004”) (depending on the condition of your wheels) and repeatable at +/- 5 microns (+/- 0.0002”).

Watch the video of the automatic ANCA wheel qualification probe in action

For instance, you’ve just loaded a wheel pack from the rack and you’re not sure if the last qualification values are still valid? No problem. Just activate wheel probing and the automatic wheel qualification process will re-qualify all critical dimensions of each wheel including:

· Wheel Diameter

· Front Surface Location

· Back Surface Location

· Toroid Radius

Simple interface to the fully automatic ANCA wheel probe qualification process

As you know, you need to find the high spot (or swept volume) to calculate the correct wheel dimensions. The software does this by repeating the measurements at several points around the wheel (we recommend 5 points as a good accuracy versus speed trade-off). It then automatically applies some clever filters to find the exact high spot for each dimension - even if it’s between measurement points. It also calculates the total wheel run-out, making it easy to identify when a wheel has been poorly conditioned and needs re-dressing.

Automatic Toroid Radius Measurement

Knowing the wheel’s toroid radius is critical for many tool grinding operations such as achieving the target OD on the first tool of a batch of end-mills. The wheel probe eliminates any guesswork or off-machine measurement by probing multiple points around the toroid and automatically calculating a best fit radius to the resulting shape.

Automatic Wheel Probe on MX7, TX7+ and TXCell

Automatic wheel probe compensation will be available as an option on all new ANCA MX7, TX7+ and TXCell tool grinders running the ToolRoom 2012 (RN32) software suite (due Feb 2012). It can also be retrofitted to many existing ANCA tool grinders. Call your local ANCA representative to see if your machine is compatible with the ANCA automatic wheel probe system, or to find out more about moving your tool production towards “Zero Manual Compensation”.

20 December 2011